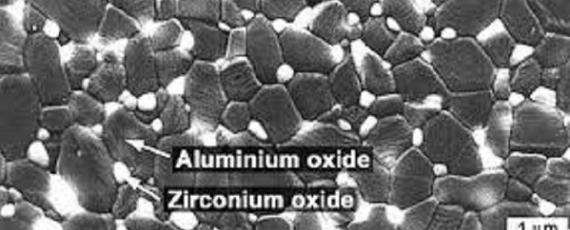

irconia-Alumina grains are made by cofusion of an Alumina – Zirconia mix in an electric furnace. The controlled fusion along with the very specific quenching process lead to a very fine crystallization with a very limited porosity. Consequently, this product is extremely tough and mechanical resistant.

| ZR series |

Two distinct grain shapes are available :a sharp grain ZR25S used in the production of hot or cold pressed resinoïd grinding wheels designed for fettling or cut-off grinding and a blocky grain ZR25B used in the production of resinoïd grinding wheels designed for metal snagging on high pressure and high speed machines. |

|

| PBZ series |

Owing to their extreme toughness, Zirconia-Alumina grains are ideal for providing very high mechanical resistance to refractory bricks and castables and are also widely used for high performance parts such as nozzles, sliding gates or impact zone refractories. PBZ can also be used as a high performance abrasive for blasting applications. Because of its higher durability, grains consumption drops down tremendously. |

Bricks and shaped materialsMonolithicsInsulating materialsBlasting |

Category: